Selecting the ideal acrylic board for your specific needs requires understanding the unique properties and applications of this versatile material. Whether you're a designer, manufacturer, or business owner looking to enhance presentations or create durable signage, the right acrylic board can significantly impact your project's success. This comprehensive guide explores everything you need to know about choosing, evaluating, and implementing acrylic board solutions in 2025.

Understanding Acrylic Board Properties and Materials

Material Composition and Manufacturing Process

Modern acrylic board manufacturing utilizes advanced polymer chemistry to create materials with exceptional clarity and durability. The production process involves polymerizing methyl methacrylate under controlled conditions, resulting in sheets that offer superior optical properties compared to traditional glass alternatives. High-quality acrylic board maintains consistent thickness tolerance and surface smoothness, which directly impacts the final application's performance and aesthetic appeal.

The molecular structure of acrylic polymers provides inherent resistance to weathering, UV radiation, and chemical exposure. This stability makes acrylic board an excellent choice for both indoor and outdoor applications where long-term performance is essential. Manufacturing techniques have evolved to include various surface treatments and additive formulations that enhance specific properties such as anti-static behavior, flame retardancy, or enhanced impact resistance.

Transparency and Optical Quality Standards

Optical clarity represents one of the most critical factors when selecting acrylic board for applications requiring visual transparency. Premium-grade materials achieve light transmission rates exceeding 92%, making them virtually indistinguishable from glass in many applications. The absence of greenish tinting, commonly found in lower-quality alternatives, ensures true color representation for display and presentation purposes.

Surface quality directly affects optical performance, with top-tier acrylic board featuring minimal distortion and consistent refractive properties. Advanced manufacturing processes eliminate internal stress patterns that could compromise visual clarity or create unwanted optical effects. When evaluating transparency, consider the intended viewing distance and lighting conditions to ensure optimal performance in your specific application.

Thickness Selection and Structural Considerations

Load-Bearing Requirements and Safety Factors

Determining the appropriate thickness for your acrylic board application requires careful analysis of structural loads, span distances, and safety requirements. Engineering calculations must account for both static loads, such as permanent fixtures or displays, and dynamic loads from wind pressure or human interaction. Standard thickness options range from 2mm for lightweight applications to 50mm or more for heavy-duty structural uses.

Safety considerations become paramount when acrylic board serves as protective barriers or structural elements. Impact resistance varies significantly with thickness, and applications involving potential human contact require materials meeting specific safety standards. Professional engineers often specify safety factors of 3:1 or higher to ensure reliable performance under unexpected loading conditions.

Thermal Expansion and Environmental Stability

Temperature variations cause acrylic board to expand and contract at predictable rates, requiring proper allowance in mounting systems and frame designs. The coefficient of thermal expansion for acrylic materials is approximately seven times that of glass, making expansion joints and flexible mounting systems essential for large installations. Proper planning prevents stress concentration that could lead to cracking or failure.

Environmental factors such as humidity, chemical exposure, and UV radiation affect long-term stability and appearance. High-quality acrylic board incorporates UV stabilizers that prevent yellowing and maintain optical properties over extended periods. Understanding these environmental interactions helps predict maintenance requirements and replacement schedules for critical applications.

Surface Treatments and Special Coatings

Anti-Reflective and Glare Reduction Options

Advanced surface treatments can significantly enhance the functionality of acrylic board in demanding visual applications. Anti-reflective coatings reduce surface reflections from 8% to less than 1%, dramatically improving readability under challenging lighting conditions. These treatments utilize microscopic surface textures or thin-film coatings that interfere destructively with reflected light waves.

Glare reduction becomes particularly important in environments with strong artificial lighting or direct sunlight exposure. Specialized treatments can maintain excellent optical clarity while minimizing eye strain and improving user comfort. The selection of appropriate surface treatments depends on viewing angles, ambient lighting levels, and the specific visual requirements of your application.

Scratch Resistance and Protective Measures

Protecting acrylic board surfaces from scratches and abrasion extends service life and maintains aesthetic appeal. Hard coating applications can increase surface hardness from the base material's 2H rating to 4H or higher, providing enhanced resistance to daily wear. These protective treatments remain optically clear while significantly improving durability in high-traffic environments.

Maintenance protocols play a crucial role in preserving surface quality throughout the service life. Proper cleaning techniques using appropriate solvents and soft materials prevent micro-scratching that can accumulate over time. Understanding the limitations and care requirements of different surface treatments helps establish realistic maintenance expectations and procedures.

Application-Specific Selection Criteria

Indoor Display and Presentation Applications

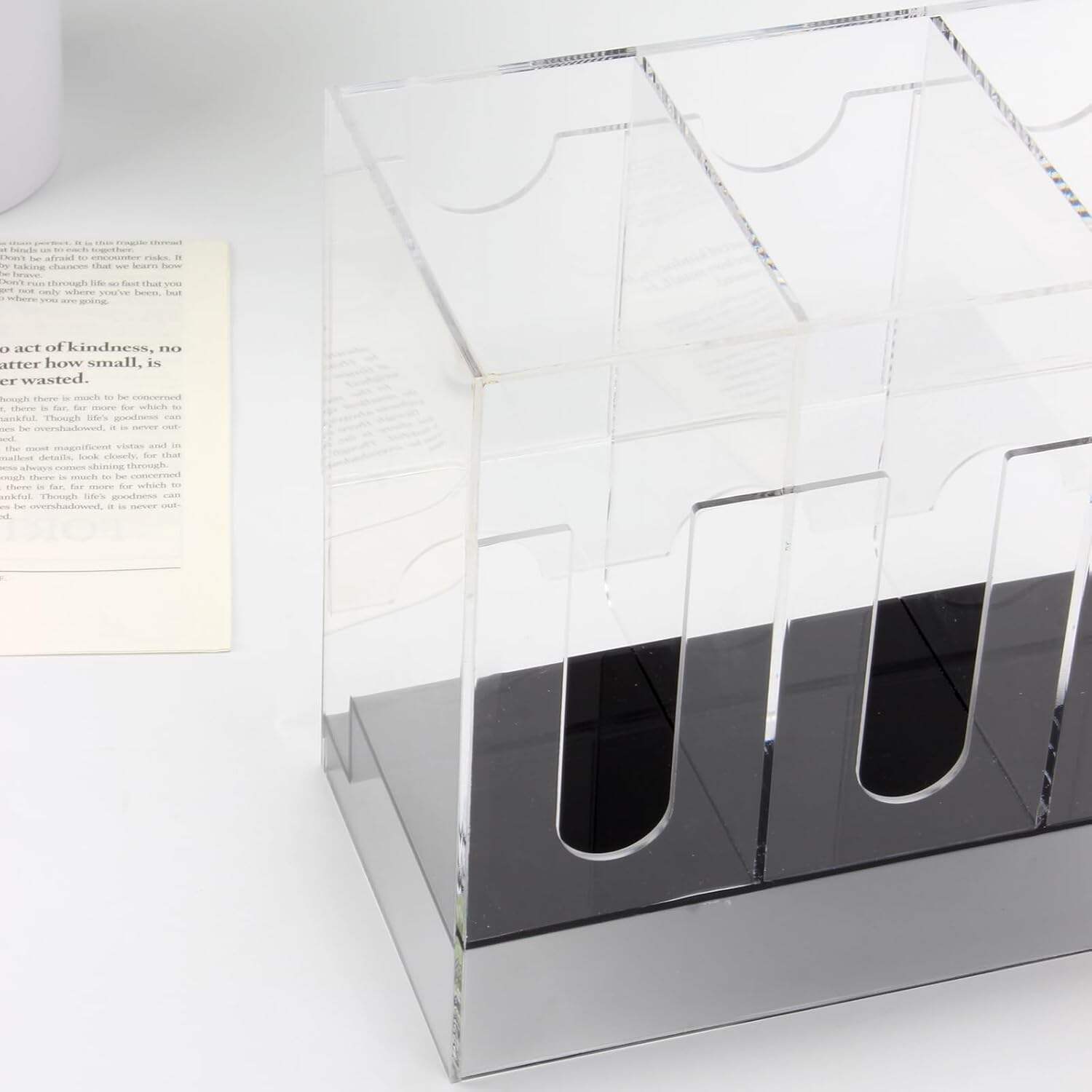

Indoor applications for acrylic board typically prioritize optical clarity, ease of fabrication, and aesthetic appeal. Conference room barriers, display cases, and presentation stands require materials that maintain crystal-clear transparency while providing adequate structural integrity. The lighter weight of acrylic board compared to glass simplifies installation and reduces structural support requirements.

Fabrication considerations for indoor use include the ability to machine, drill, and polish edges to professional standards. High-quality acrylic board accepts various joining methods, from solvent welding to mechanical fasteners, enabling complex geometric designs and custom configurations. The material's thermoplastic nature allows for heat forming and bending to create curved surfaces when required.

Outdoor and Weather-Resistant Applications

Outdoor applications demand acrylic board with enhanced weather resistance and UV stability to maintain performance over extended exposure periods. Marine environments present additional challenges from salt spray and humidity that require specialized material grades. UV-stabilized formulations prevent the yellowing and embrittlement that can occur in standard materials under prolonged sunlight exposure.

Wind load calculations become critical for large outdoor installations, where acrylic board must withstand significant pressure differentials and dynamic loading. Proper edge sealing and drainage design prevent water infiltration that could compromise structural integrity or create visual distortions. The thermal cycling experienced in outdoor applications requires careful attention to expansion joint design and mounting flexibility.

Quality Assessment and Testing Procedures

Visual Inspection and Optical Testing

Comprehensive quality assessment begins with systematic visual inspection under controlled lighting conditions to identify surface defects, optical distortions, or contamination. Professional evaluation protocols use standardized viewing distances and illumination angles to detect subtle quality variations that might not be apparent under casual observation. Digital imaging techniques can document surface conditions for quality records and future comparison.

Optical testing procedures measure critical parameters such as light transmission, haze levels, and color characteristics using calibrated instrumentation. These quantitative assessments provide objective quality metrics that enable comparison between different suppliers or material batches. Regular testing throughout the supply chain ensures consistent quality and identifies potential issues before installation.

Mechanical Property Verification

Mechanical testing validates the structural performance characteristics essential for safe and reliable service. Impact resistance testing determines the material's ability to withstand sudden loads without catastrophic failure. Tensile and flexural strength measurements confirm compliance with design specifications and safety requirements for structural applications.

Long-term stability testing evaluates performance under accelerated aging conditions that simulate years of service in compressed timeframes. These tests reveal potential degradation mechanisms and help predict service life under various environmental conditions. Understanding mechanical property variations with temperature, humidity, and chemical exposure enables informed material selection for specific operating conditions.

Installation and Mounting Considerations

Fastening Methods and Hardware Selection

Proper fastening methods are crucial for maintaining the integrity and appearance of acrylic board installations. Mechanical fasteners must distribute loads evenly to prevent stress concentration around mounting points. Oversized holes and flexible washers accommodate thermal expansion while maintaining secure attachment under varying environmental conditions.

Hardware selection requires consideration of material compatibility to prevent galvanic corrosion or chemical interactions that could compromise long-term performance. Stainless steel fasteners provide excellent corrosion resistance, while specialized plastic hardware eliminates the risk of galvanic corrosion entirely. Proper torque specifications prevent over-tightening that could induce stress cracking around fastener locations.

Edge Sealing and Weather Protection

Effective edge sealing protects acrylic board installations from moisture infiltration and environmental contamination. Structural glazing sealants provide weatherproof barriers while maintaining flexibility for thermal movement. The selection of compatible sealant materials prevents chemical interactions that could cause crazing or other surface damage over time.

Proper drainage design prevents water accumulation that could create freeze-thaw damage in cold climates or promote biological growth in warm, humid conditions. Weep holes and drainage channels must be strategically located to remove moisture while maintaining structural integrity and aesthetic appeal. Regular inspection and maintenance of sealing systems ensure continued weather protection throughout the service life.

Cost Analysis and Value Engineering

Initial Investment Considerations

The initial cost of acrylic board includes not only the material price but also fabrication, installation, and any specialized treatments or coatings required for the application. Premium materials with enhanced properties command higher prices but often provide superior long-term value through improved durability and reduced maintenance requirements. Comprehensive cost analysis must consider the total project lifecycle rather than focusing solely on upfront material costs.

Volume purchasing and standardized dimensions can significantly reduce material costs for large projects. Working with suppliers to optimize cutting layouts minimizes waste and reduces overall project expenses. Early engagement with fabricators during the design phase enables cost-effective solutions that meet performance requirements while controlling expenses.

Long-Term Value and Maintenance Economics

Long-term value analysis considers maintenance requirements, replacement schedules, and performance degradation over the expected service life. High-quality acrylic board materials often justify their premium cost through reduced maintenance frequency and extended service intervals. Proper material selection can eliminate the need for protective films or frequent replacement that adds to operational costs.

Maintenance economics include not only direct costs for cleaning and repairs but also indirect costs from downtime or reduced functionality during maintenance activities. Materials that maintain their appearance and performance with minimal intervention provide significant value in high-visibility applications where downtime creates business impact. Energy costs for climate control may also be affected by the thermal properties of the selected acrylic board materials.

FAQ

What thickness of acrylic board should I choose for a protective barrier application

The appropriate thickness depends on the specific protective requirements, span distance, and potential impact forces. For standard office partitions with spans up to 1 meter, 6mm thickness typically provides adequate strength and stability. Higher-risk applications or longer spans may require 10mm or thicker materials. Consult with a structural engineer for applications involving significant loads or safety-critical functions to ensure proper thickness selection and mounting design.

How do I prevent acrylic board from yellowing over time

Yellowing prevention requires selecting UV-stabilized acrylic board materials specifically formulated for long-term clarity retention. Avoid exposure to certain cleaning chemicals and high temperatures that can accelerate degradation. Quality materials from reputable manufacturers include UV inhibitors that maintain optical properties for decades under normal indoor conditions. For outdoor applications, choose marine-grade or architectural-grade materials with enhanced weather resistance.

Can acrylic board be repaired if it gets scratched or damaged

Minor scratches in acrylic board can often be polished out using progressively finer abrasives and polishing compounds. Deeper scratches may require flame polishing or professional restoration services. Crack repairs are more challenging and may compromise the structural integrity of the material. Prevention through proper handling, protective films during construction, and appropriate surface treatments provides the best long-term solution for maintaining appearance and performance.

What are the key differences between cast and extruded acrylic board

Cast acrylic board offers superior optical clarity, better chemical resistance, and easier machining characteristics, making it ideal for high-quality applications requiring precise fabrication. Extruded acrylic board provides more consistent thickness tolerance and is typically more cost-effective for applications where absolute optical perfection is not required. Cast materials generally have better stress-cracking resistance and can be flame-polished to achieve superior edge quality for visible installations.

Table of Contents

- Understanding Acrylic Board Properties and Materials

- Thickness Selection and Structural Considerations

- Surface Treatments and Special Coatings

- Application-Specific Selection Criteria

- Quality Assessment and Testing Procedures

- Installation and Mounting Considerations

- Cost Analysis and Value Engineering

- FAQ